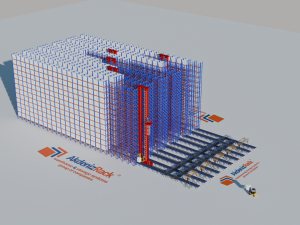

AS/RS Automatic Storage and Retrieval Systems

An Automated Storage and Retrieval System (ASRS) consists of

Rack Systems, Stack Lifting Crane Systems, Automated Guided Vehicles (AGVs),

Autonomous Mobile Robots (AMRs), Conveyor Systems, and Management and Control

Systems. This system represents the most advanced automatic technology used in

the logistics industry. In the rack system, storage areas are available in all

standard sizes. AS/RS is widely used in various industries. It comprises

assembly racks and welding racks. Supported by transfer loaders, conveyor

systems, and computer control systems, it ensures the fullest utilization of

storage space, transportation mechanization, and modernization of storage

management.

ASRS with Pallet Racking Feature

The automated storage and retrieval system comprise rack

systems, crane systems, conveyor systems, and management and control systems.

This system represents the most advanced automatic technology used in the

logistics industry. In the rack system, storage areas are available in all

standard sizes. The automatic crane operates within the rack system and

facilitates load access. AS/RS is widely used in various industries. Pallet

racking ASRS utilizes selective pallet racking as the rack system. The main feature

is that each level consists of cargo of the same size. Clearance is arranged to

face the rack aisle for crane travel and cargo access.

Multi Layer 4 Way Shuttle System

A system called the "Multi Layer 4 Way Shuttle

System" is a type of automated storage and transportation system. This

system is used for storing, retrieving, and transporting materials in a

warehouse or manufacturing facility. It is commonly used to meet large-scale

storage needs and is frequently seen in modern storage and logistics systems

with high levels of automation.

This system typically consists of the following

components:

Storage Area: Usually created using rack systems or

specialized storage units. It represents the area where materials are stored.

4 Way Shuttle: This is an automated vehicle used to

move materials within the storage area. It can move in four directions

(forward, backward, right, and left) and transports materials within the rack

systems in the storage area.

Multi-Layer Structure: This system organizes the

storage area into multiple layers, providing more storage capacity in the same

area.

Control System: Typically an automation system

managed by a computer or central control unit. It controls the flow of

materials, manages inventory, and monitors system performance.

This system enables effective storage and management of

materials in the storage area. Thanks to its automation features, material

movement and inventory management are carried out automatically without the

need for human intervention. This reduces labor costs and increases warehouse

efficiency.

This system has many advantages, especially in terms

of automation and efficiency:

1. High Capacity: The Multi Layer 4 Way Shuttle

System increases storage capacity and allows for more efficient use of

available space due to its multi-layered structure. 2. Automation: With

its automatic operation feature, it minimizes human intervention and automates

storage processes, reducing labor costs and error rates. 3. Fast Access:

The system's multi-layered structure provides fast access to products,

shortening order preparation times and increasing customer satisfaction. 4. Flexibility:

The Multi Layer 4 Way Shuttle System can be used flexibly for different types

and sizes of products, allowing the storage space to be adapted to various

needs. 5. Less Storage Space Requirement: Thanks to its vertical

structure, less horizontal space is needed, resulting in cost savings in

property costs. 6. Efficiency and Cost Reduction: Factors such as

automation, fast access, and more efficient use of space increase overall

efficiency while reducing operating costs. 7. Sustainability: Factors

such as reduced space usage, energy savings, and lower labor requirements

provide advantages in terms of sustainability.

Stacker Crane + Pallet Shuttle System

The Radio Shuttle and stacking solution enable the dense

storage of palletized products. Leveraging mature stacking technology, the

system achieves dense storage functionality by increasing tunnel depth and

reducing the number of stackers. Additionally, it enables the fully automatic

operation of shuttles, stackers, conveyor machines, and other equipment through

the use of WMS/WCS control systems. This system significantly increases

material density in the warehouse, performs random storage according to FIFO

logic, eliminates forklift passage, and supports storage space. As a result, it

reduces forklift entry and exit times, decreases workers' operating time, and

meets customers' dense storage requirements. Crane-supported pallet handling

systems are used in warehouses or industrial facilities for the automatic

storage, transportation, and placement of materials. They are preferred in

large storage facilities and facilitate the rapid processing of large quantities

of materials. These systems have an integrated structure of cranes and pallets.

Cranes lift and lower materials by moving along rails, while pallets facilitate

the movement of materials and are typically durable metal or plastic platforms.

The system optimizes warehouse management by working in coordination with

automation and control systems. These systems are commonly used in large

distribution centers, manufacturing facilities, and logistics centers,

utilizing warehouse space more efficiently and reducing labor. High Storage

Capacity: It provides maximum storage capacity by utilizing vertical

storage space. Automation and Efficiency: By its automatic operation

feature, it automates material handling and storage processes, thus speeding up

operations and reducing human errors. Quick Access and Organized Storage:

It enables quick access to materials and organizes storage space in an orderly

manner, facilitating easy retrieval of materials. Labor Savings: Automatic

storage systems require less human labor compared to manual operations, which

can reduce operating costs. Flexibility: It can have flexible

configurations to adapt to different storage needs and pallet types.

Stacker Crane With Conveyor System

The system comprises high-level stereo racks, automatic

stacking, a conveyor line, Warehouse Control System (WCS), Warehouse Management

System (WMS), and associated peripherals. Depending on actual application needs

and investment budget, the Palletizer can be single/double-row, flat/fork type,

or other different variations. The retrieval unit can select trays or material

boxes, while the conveyor line may prefer a drum-type conveyor.

Stacker Crane with Conveyor System is an automation

system used in warehouses or manufacturing facilities. This system facilitates

the storage, transportation, and processing of materials, making it ideal for

managing intensive material movement in large warehouses and manufacturing facilities.

This system consists of two main components:

Stacker Crane: A machine that can move on warehouse

rack systems and access high shelves. It operates automatically and is

controlled by computer or programmable logic controllers.

Conveyor System: Enables the transportation of

materials from one point to another. Various conveyor types are used depending

on the type and size of the material.

Stacker Crane with Conveyor System automates the

retrieval, storage, processing, and shipment of materials. This increases

efficiency, reduces errors, and ensures effective use of warehouse/production

space.

Advantages: High Storage Capacity: Stacker Crane is

an automatic system capable of vertical storage. This increases storage

capacity and allows more products to be stored within the same area. Automatic

and Fast Operation: Stacker Crane operates automatically and when

integrated with a conveyor system, it can quickly pick up, store, or transport

products. This increases warehouse efficiency and reduces the risk of human

error. Space Efficiency: Vertical storage allows for more efficient use

of warehouse space. This advantage enables maximizing valuable space to fit

more products within the same area. Workplace Safety: Stacker Crane and

Conveyor System minimize human intervention, enhancing warehouse worker safety

as direct contact with hazardous equipment is not necessary. Time and Cost

Savings: Automatic operation and fast processing lead to time and cost

savings in businesses. Faster product handling, storage, and shipping processes

generally improve overall operational efficiency. Lower Operating Costs:

Implementing automatic systems can reduce operating costs in the long term.

Decreased labor requirements can lower labor costs, and automatic systems

requiring less maintenance can reduce maintenance costs. Data Monitoring and

Management Ease: Stacker Crane and Conveyor System are often integrated

with automation and data monitoring systems. This makes inventory management,

stock tracking, and transaction data monitoring easier, aiding business

managers in making better decisions.

-300x225h.png)

-300x225w.png)

-300x225.png)

-300x225h.png)

-300x225w.png)

-300x225w.png)

-300x225h.png)

-300x225w.png)

-300x225h.png)